I like to build tube amplifiers, maybe you’re somebody with similar interests if you’re viewing this website. I thought it would be awesome to be able to test tubes, and also curve trace them to see how they perform under different circumstances. This led me to years of tinkering and searching for the best kit to make this happen. A few years of that, and a whole lot of money invested later, I was back to square one.

What happened? Well, I had found my way to a fairly popular tube tracer kit. It had potential, but never quite worked right. There were always problems with accuracy, inconsistency, and worst of all, parasitic oscillations. I chased down those parasitic oscillations for years. Thinking there was something wrong with how I configured my hardware around the tracer circuit. I was wrong.

On the website for the tube tracer I was using at the time, there were a lot of tips and ideas to improve and protect the circuit. I tried one, thinking that of course it was a tested and safe method, or why else would it be presented publicly as such? Well, it fried my old tracer’s firmware chip. When I contacted the undesirables that sell said tracer, they got mad at me and blamed me for the issue I tried to warn them about on their website. At that point they told me they would not help me ever again, or replace my firmware chip. I sent them a colorful email letting them know how I felt.

The Birth of the FUtracer

After investing a lot of money and hundreds of hours into this project, I wasn’t going to give up. So I decided to assess the situation, and make something better. The previous tracer’s PCB was absolutely terrible quality. Embarrassing even. I mentioned this to the designer of it, and I guess they didn’t appreciate that either. It was seriously pathetic. They didn’t have through-hole plated vias, the traces easily lifted off the PCB, the masking was mediocre. So I designed a new PCB, with better design methods, through-hole plated vias, better trace layouts and sizes, etc. Then I ordered it from a fantastically more qualified manufacturer.

Now I needed firmware. I wasn’t going to learn a new programming language, so I hired somebody to program it for me. They did an AWESOME job. They also helped me work out the kinks in the alpha and beta versions of the board, which lead to the excellent FUtracer tube tracer PCBs now available. The beta version of the board is also fully operation, but the final versions now also include static protection for the USB circuit.

A FUnctional Curve Tracer

Now here’s the funny part. I spent years chasing down what I thought were parasitic oscillations. I took my new PCB, and my new proprietary firmware, and I installed it in my old tracer’s rig. Poof. Just like that, no more parasitic oscillations. In other words, it wasn’t my hardware setup, it was flaws in the (now) competition’s firmware. Then I built a new, smaller rig with the new tube socket PCB I designed, and I have a significantly more useful device.

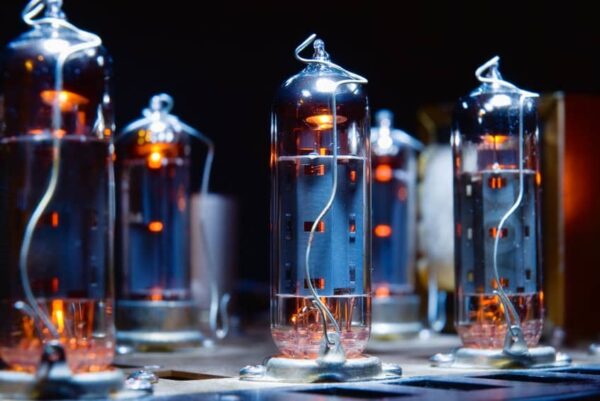

Finally, if you’re a vacuum tube enthusiast, or a musician that loves tube amps, get yourself an FUtracer set. I’m not selling mediocre components to make a profit off a bunch of trash like some people do. Above all, I have a BOM with all top quality parts listed that you can purchase directly from your favorite supplier(s). Build it, and enjoy. (Note: SMT socket board version shown. You can choose between SMT or through-hole tech for the socket board. Or both.)

What Makes the FUtracer Different?

To sum it up, I was asked what was different between this project and the one I had a bad experience with. This was roughly my response:

“There are a number of design improvements, circuit changes, component changes, and better quality in general. The result is a faster, and far more reliable product. Yes, also PCBs for tube connections, and external PSU connections. There’s no mediocre heater power supply on the main PCB either- an external PSU is required, and does a much better job.

The firmware is also a huge difference, the “other project’s” firmware is not great. Incapable of properly testing a number of tubes. I spent years tinkering and chasing down what I thought were parasitic oscillations, but turned out to be flaws in his hardware/firmware. I swapped his board out with mine in my old tester, and instantly those issues were gone with all else being the same.“